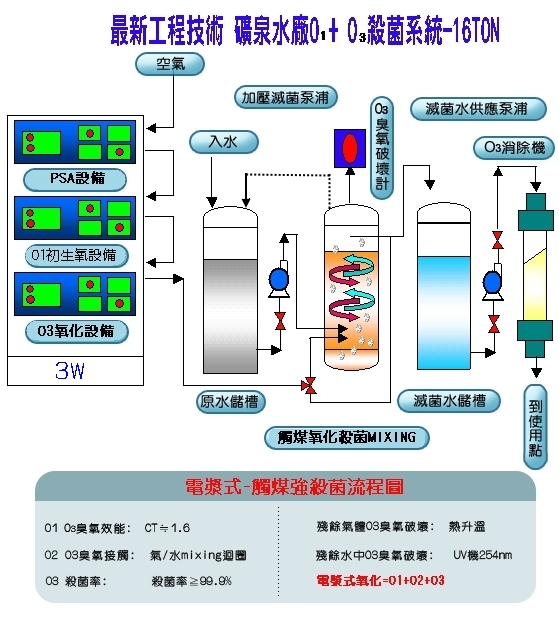

3Water electric thick liquid type touches coal O1 +O3 strong sterilization system

It is deep in ocean water /low for carbonic acid drink body of * bottles disinfect not disinfecting /

Main fact Purport

Produce high thickness O1 (come into being attitude oxygen ) , strong sterilization ink of strength used for being filled with the high mineral water of PH 9, and have small molecule sterilization water of the long result type.

High hydrogen ion index (PH =9)The mineral water is difficult to mix with the ozone, because the thickness of ozone improves and will reduce hydrogen ion index. Need to add 1.7 of original PH7 coefficient

~2.0 times, the water yield improves from 5TON to 16TON about 3 times, amounts to power of about 5 times.

Say Bright

This brand-new practical food grades of strong sterilization system, strong to disinfect single oxygen O1, drug effect 産It is direct , is facing the fungus cell to launch and clever to grow

Bright cruising missile, and the name of this guided missile is exactly by single oxygen O1 that the ozone is appeared , so can order 爲"Single oxygen treatment.. So adopt 3W

Electric thick liquid type strong to disinfect systematic O1 system to touch coal.

It is not good that the general angry liquid of ozone mixes the system and dissolves efficiency on the market, the single engine (host computer ) is unsuitable to work for a long time. The high fever will take place

Reduce the thickness of the ozone and power consumptive, so need to do the larger producing amount of thickness of ozone; 3W adopts the host computer with double engines.

The electric thick liquid type touches the coal Systematic advantage :

1. The high fever will not take place: So 300% of the power consumption of host computer that the province electricity is sold for the city.

2. Oxygen O1 was several hundred times of sterilization strength of O3 that the ones that just formed came into being. "Single strong sterilization law of oxygen. Single Electrode Corona

Discharge) produced the low-temperature plasma.

3. This system mixes the law for exclusive many sections of types , the angry liquid mixes and dissolves good 20000% that sold for the city of efficiency systematically.

4. Excite the sub ion attitude of the moisture and break steeping the sterilization water that is a long result type a little of the key

5. With double engines (a/b host computer ) to replace operation, the systematic life-span increases by 3-5 times sold for the city

6. The electric thick liquid system discharges the way hydrolysises and touches the coal O1 system, can resolve bacteria to eliminate completely , magnetism can little member water after filling with, can be here

In charge of forming and oxidizing the cover membrane and is protected and in charge of the wall in the wall, prevent oxidizing once again, can lengthen the life-span of the water pipe .

Scope of application

The bottle bodies of all kinds of drink , drinks , cosmetics disinfect

|

¡ñ¡ð¡ñThe mineral spring water-washes the bottle and is filled with the procedure of the packaging ¡ñ¡ð¡ñ Step 1 |

Empty bottle washed to wait examine and hand over to the conveyer belt. |

|

Step 2 |

Have the bottle to wash the bottle machine automatically |

|

Step 3 |

Is it touch with 3Water coal (come into being attitude oxygen ) steep a little , brush develop 22 seconds such as dirt such as outside such as bottle to hydrolysis |

|

Step 4 |

Washing uses the recovery water of Final Rinse to gush out to wash with the high pressure. |

|

Step 5 |

Wash and use containing the filling with water and making the last washing sterilization of ozone. |

|

Step 6 |

The third section of empty bottles washed after sterilization , send into the aseptic room and wait for being filled with automatically |

|

Step 7 |

Is it cover and after ozone sterilization , wait for one stamp to send off automatically. |

|

Step 8 |

Filled with one after building automatically, send the storage |

The electric thick liquid type is hydrolysised- the sea water touches the coal and disinfects the comprehensive norm proves (consult and use)

Equipment name : The electric thick liquid type- touches the strong sterilization system of coal (deep sea water is special-purpose)

Microwave & Dielectric Barrier Discharge of Micron Bubble O1 Water

Deal with the target : The whole packing facilities of mineral water.

Suitable for mineral water , o2 mineral water equipment , beverage O3 the drink of washing bottle machine , oral liquid , drug , wine etc..

Give sterilization + activation function

CD corona discharges the ozone pours into and adds Dielectric Barrier Discharge -Enduring the rice to steep a little of high-frequency electric thick liquid ¡.. Airtight and at odds with the community or the leadership

Under the strength high pressure, inject the ozone into water, on one hand disinfect and disinfect . Can in in charge of wall is it oxidize leather membrane protect to form after clean on one hand

In charge of the wall , prevent the fungus from increasing by * and lengthening the water pipe , filling machine , sealing the life-span of the overlaying machine fast once again .

High-frequency electric thick liquid is it touch coal is it adopt electric thick liquid zone time air , pure oxygen to disinfect to hydrolysis, the oxygen molecule key is broken, produce the single oxygen atom,

And then combine with other oxygen molecules.

The enduring the electric chemical characteristic of one meter of zero price metal of high-frequency electric thick liquid is produced and detoxified / steeped and purified superstrongly in the twinkling of an eye a little, touch the mere wavelength of magnetism and particle of the coal machine

Absorb then a large amount of nature energy make use of device this release brute force living aqueous cleaning function of air. Its response, in order to excite the gas

Ion attitude, break the key, the macromolecule turns a little member, to reach and activate water quality.

3Water technological characteristic

1. It hydrolysis touch high efficiency coal sterilization /wash not spraying cost not low sterilization the deodorization systems exposing to the sun angry to float except that ( OZONE)

High thickness O3 is totally dissolved in water, accord with the international safety standard , is never harmful to human body.

2. Hydrolysis and touch coal O3 equipment suitability high: Can deal with the demand and design the suitable model in accordance with the customer .

3. Psa utilizes air process around to formate the special-purpose member and sift to absorb the trough and absorbing most nitrogen

4. Psa amount produces and melts the equipment: Can finish delivering installing and maintenance during the shortest time . 5. Set up the expenses , safeguard the cost economily cheap for the first time: It is low to purchase the expenses , replace operation 24 with A/B two system with double engines

The whole automation mechanized operation in succession of hour, it is with high efficiency to use , must be managed by special messenger, the regenerative material is cheap and service life is long.

6. Easy and simple to handle , operate the stability high: The whole automation mechanized operation, the equipment highly stabilizes the characteristic.

The high-frequency electric thick liquid of 3w oxidizes device characteristics

/

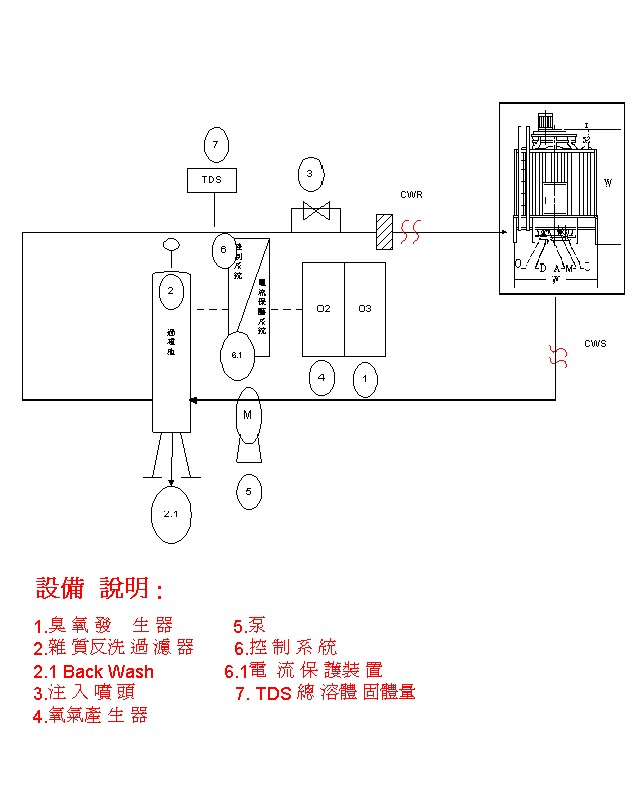

O3 of flowing type (SIDE-STREAM ) by Dielectric Barrier Discharge -MB-A *B *C *D four kinds of water process systems

,Water in water trough is taken out (PUMPS ) to use the water pump to collect the waste water in the water tower , make from a psa oxygen source or the atmosphere

O3, then will utilize Wen's shower nozzle (VENTURI INJECTOR ) to pour into water , has strong O3 sterilization result, can

The fungus is counted and reduced. The fungus that O3 washes the bottle counts the organic impurity or the inorganic impurity and is washed the tower by inverse well-flushing and collected and removed , so wash reducibly

The tower fungus counts the pollution sources.

Circulation procedure: Coherent circulation by this sterilization system adopt (flowing type)

Modelling : Dielectric Barrier Discharge is it touch coal and O3 in charge of in the same system , can't disperse independence , with true to hydrolysis

Protect systematic stability

Quantity : A system: The size can't be greater than 3.5m *3m *2.0m, or need to cooperate with the on-the-spot space in order to assemble

(1)Construct: :

(the material outer cover of SS41) hold and is in charge of by touching the coal in order to the in charge ofing type sealed conductive alloy powder, charter covering and is in charge of quartz in SUS3), and have

Able to bear the moist function, protect packs of 304 SUS is it cover to wrap up , can take place corona (Corona Discharge ) way produces high purly firm one year

Degree oxidizes the gas strongly, the other case enters to adopt 4 with exhaust angrily " the fan, keep ventilating well

(2)Deal with the capacity systematically: For the above thickness of 0.5-0.8ppm foul smell at least (very much groups connect in parallel and use)

(3)A lot of section is oxidized and mixed: One section: It it is multi-layer to be adopt by type barrel trough with the low-voltage(<2-5kg/cm2) oppress there aren't gas:

The flowing type sucks the surplus gas by connecting by-pass (quarry PVDF material, the ones that have anti-oxidant and acidproof soda are mixed excellently, utilize and shoulder

It keep principle it make gas and water unable to mix ) pipe diameter (1-3 ),wavelength> needn't use drug not chemical of 4¦Ìm, prevent the pipeline from forming the dirt ,

Corrode , lengthen the life-span of the equipment

(4)Thickness: (a)The above of 1.66.7% wt air (b is for the apolegamy ) is in many sections of systems of oxidizing at least in the air> 0.50

Ppm ppm 0.88ppm can include the pure producing amount 5g/min of oxygen and ozone of PSA system (855% ) , include the air compressor, the air is dry

Device and the filter , ozone generator and adverse current preventing device, the gentle type is in charge of the filler, the ball valve , going against to stop the valve , manometer, can control

Equipment ON/OFF pressurized pump of ozone treatment.

(5)Monitoring system: (match)

Adopt and monitor and dissolve the appearance of thickness of ozone or TDS *1 (the display of amount of solid dissolved ) , ORP *1 (ORP Controller oxygen

Is it reduce electric potential display to take), used for sustaining control circulating water is it reduce electric potential / conductance degree and the green light shows *1 when turning round to oxidize

(6)Horsepower: >=1HP/2hp, enter water mouth 1-2 ", use the circulation pump that the stainless steel or the acidproof soda used, anti-oxidant.

(7)The pipeline assembling

(1)By last inject not linking up valve of pipeline not open piece (2 ) oxidize there aren't gas the pipelines

(3)Enclose GAS by preventing oxidizing the gas backset current against stopping the valve inside

(8)Gas system

Enter and quarry the oxygen generator that the dry air may cooperate with pressures to exchange adsorptions methods (PSA ) angrily in order to improve the thickness of ozone, its oxygen

The purity is with 855%, its relative dew point is: -603 degrees Centigrade of compressed air are input in 5 Kg/Cm2

(9)Circuit respect of the safe respect: Because safe is it is it make earth and leak electricity *1 circuit breaker to need to operate steadilying. Insert while operating, stop

Can also show that the power is still here bright at the time of the chance , has not cut out .

Gas respect: PSA like because too heavy can YHTYT competent to close since in pressure or moisture.

(10)Being dispatched from the factory bright (1) equipment type is being recorded / pursued to operate the servicing manual in 2007 Chinese of magnetic disc of surface.

Two, the large-scale ozone of 3Water washes and sprays the sterilization manufacture system- sell in other areas

(Large-scale food industry , sea-farming support the family in the project , field of water purification , food sewage disposal field and retrieve industry and is all suitable for this department

The interconnected system is adopted, the planning but separately)

This ozone making machine used of project includes air's making facility , ozone producing machine , flow of ozone and distributing one systematically,

The ozone contacts the devices , such as the trough and atmosphere ozone destroying device ,etc.. Power , quantity that the ozone system needs, like the form specification form of the equipment

Show, constructing should propose sending and examining the materials and can just be adopted to do the manufacturer after verifying. The ozone making

The institute shows to make the general norm of the system equipment as follows :

¡¤ The air makes facilities: The air quality of offering the ozone machine to need should be very clean and dry, so in the ozone

Should set up three groups of accurate filters , a group of automatic drains and dry aircrew of low temperature in front of the machine air inlet.

{It is top to sell in other areas }Allocate the sterilization manufacture system producing machine :

• It produces the ozone way to adopt Dielectric Barrier Discharge and discharge

• The ozone outputs the capacity: 300g/hr. Book in accordance with the capacity demand on the equipment form.

• Electric demand: 220V,60HZ • Atmosphere temperature : 5 - 40 degrees Centigrade • The environment ventilating : Change the air amount six times at least per hour

• Cold cathode CORONA of low frequency is put; Electricity water-cooled cooling electrode • All produce the mould group 316L stainless steel

• Include the key type pure oxygen producing machine • Hit the reducing value of oxidizing moisturly and detect the examining device and control device inside. • But the mode ozone is exported.

• Totally isolate discreditedly when close • The automatic flow of air supply is controlled in order to maintain the vacuum • Ampere and voltmeter show that the electric current offers the state

• The other case accords with NEMA 3R norm dampproofly • Cut out to protect promptly • Control remotely : Alarm , air that cut out , fall promptly

The thickness of ozone is detected and examined and ORP is controlled

• The mistake is protected: Pour flowing water , case door opening , return circuit mistake , supporting the insufficient , distorted empty or excessive vacuum of atmospheric pressure strength , protecting overheatedly .

• All return circuits have fuses that are protected • Protect firm time limit : The whole machine is protected for firm year, the high-pressure electrode is managed for one year 3.The flow of ozone distributes one ¡¤

Regard 304/316 of the stainless steel as and distribute the support • Put inside 1/ 4 " pipelines of sum that PVDF mix "

• Assign and should include an electromagnetic valve , floodgate valve to export in every flow • Adopting and drifting along the flow meter (ROTOMETER ), the capacity is 10L / MIN,

The floater is with 316 stainless steel or iron Fluorine dragon material, an organism , in order to press one gram of strength Material • All connection packages are iron Fluorine dragon materials • Assign another end to set up manual drains

The ozone contacts the trough :

• Adopt PE and FRP polymorphous barrel trough (COMPOSITE TANK ). • Winding type that FRP makes and adopts rolling vertically and horizontally .

• Upper and lower openings are connected by 3 more than inches of Fran in Great Britain . • Try pressing in static behavior: 150PSI, working pressure is in 50PSI

• The lower floor has six ABS plastic apron device watersupplily • The upper strata surface for ABS porous apron device • PVC triangular base

Stand 5. Atmosphere ozone destroying device • The destroying device outer cover material is 316 stainless steel • Include it altogether inside The heating of 1KW is excellent • Include inside

CUO and composite ozone of MGO destroy catalysts • Exhauster capacity ozone computer lab space 6 times / hour • 316 stainless steel ozone destroys the scattered air plate of catalyst • Bottom drains

/

3Water adheres to the first of quality , hearty service , management idea at fair price, it is full-automatic to set up /The semi-automatic ozone has the bottle,

|

Hydrolysis and touch the coal and is filled with , sealed the covering machine , ozone disinfecting machine ,etc., the production process is filled with the packaging in the aseptic room �@The electric thick liquid hydrolysises and touches the coal systematic specification and function of sea water 16 tons per hour Type |

Model |

S16T-250/280g-D/C |

SJ16t-300g/B |

SJC16t-300g/A |

|

|

Necessary space of machine |

L * M * H (consult) |

120*100*150cm *3 |

135*110*155cm *3 |

>150*110*155 *3 |

|

|

16ton sterilization rate |

% |

99/99.99% |

110% |

120% |

|

|

Handling capacity |

TON |

16 |

16.2 |

16.3 |

|

|

Thickness of ozone and water |

ppm |

>0.5 |

>0.5-0.6 |

>0.5-0.8 |

|

|

With double engines / two is systematic |

Engine |

A/B two system with double engines replaces operation |

A/B two system with double engines replaces operation |

Two systems with double engines replace operation |

|

|

Micron /endure Mi mix |

Micron/NANO bubble

|

The micron / each mixing |

Each is mixed- steep very smallly |

Endure the rice to mix- steep ultra tinily |

|

|

Weight |

KG |

300-450 |

400-480 |

420-480 |

|

|

Material |

The case body / in charge ofing type generator 3A/4A-18L (RE-70-1812 ) inside outside Ss41 |

SUS304 |

|||

|

The high-pressure quartz is in charge of the sterilization appearance |

Ozone output(O3 g /h) |

260/300 |

320 |

320 |

|

|

Thickness of ozone |

Concentration(g O3/m ^ 3) |

More than 60/70 |

More than 75 |

More than 80 |

|

|

Oxygen / the high-pressure oxygen inputting |

Inject Air/O2(m ^ 3/h) |

2/2.5 air |

3.3 Oxygen |

4.5 Asp Oxygen Concentrator |

|

|

Output the pressure |

Outject -pressure |

0.6/0.8 kg/cm2 |

0.6-1kg/cm2 |

0.6-1.2kg/cm2 |

|

|

Running water function Supply the velocity of flow |

Flow/lpm |

267L/min |

270L/min |

275L/min |

|

|

Excite and break the key and steep the ion attitude a little |

Micron |

1 |

0. 5 |

0.05 |

|

|

Cooling system |

Cooling System |

Fan * 6/8 |

Fan * 8 |

Fan * 8 |

|

|

The power supplying |

Supply Powder |

220V-50HZ /one-way |

110V-60HZ 220V-50HZ |

110V-60HZ 220V-50HZ |

|

|

Every 150g power consumption power ratio |

150g/h*W |

4500w/4300w |

4300w |

4000w |

|

|

The angry liquid is mixed excellently |

Inject |

2" |

2.5" |

3" |

|

|

Mix the number of times |

Time |

3 |

4 |

5 |

|

|

Service life /annual |

Years |

>5 |

>10 |

15 |

|

|

MICRON micron steeps ion attitude Budget cost (the second set is favourable ) |

Price ten thousand |

588/689

(538/620 second preferential price) |

900

810 (the second set of preferential prices ) |

1100

950 (the second set of preferential prices ) |

|

|

Response that the high thickness oxidizes |

O1+O3+micron-B |

The aura discharges Single oxygen treatment |

Cold corona discharges Single oxygen treatment |

High energy electron (energetic electron form oxygen treatment |

|

|

Sell in other areas and allocate toply

|

Lie between the discharging law of electric quality / cold electric thick liquid or the electric thick liquid of low temperature (cold plasmas; nonthermal plasmas, NTPs) |

||||

| �@ | �@ | �@ | �@ | �@ | �@ |

|

The airtight type high-pressure generator of tube / flat generator comparison sheet Generator |

Airtight type high-pressure generator of tube |

Flat generator |

|

Price |

Quite economic |

There is much consumptive material |

|

Way to disinfect |

1.Oxygen O1 was several hundred times of sterilization strength of O3 that the ones that just formed came into being. "Single strong sterilization law of oxygen. Single Electrode Corona Discharge) produced the low-temperature plasma. 2.O1\O3\ magnetism can, trinity strong sterilization |

1. Produce the high temperature 2. Single O3 sterilization law |

|

Life-span |

Lower 10-15% in longe-lived year The high-frequency electric current of high pressure of direct current is able to bear openly moistly , so longe-lived |

Short-lived- lower 60% in one year Law of point discharge: The electron beam is low in thickness, will produce the spark, temperature will rise but have supposition of producing NOx and life-span of influence. |

|

Long run in succession |

Oxygen o1 of attitude that the result disinfecting can long run and come into being in succession |

It will produce high fever o3 to long run in succession |

|

Power consumption of the generator |

This new-type province electricity , low power , efficiency of the high thickness. This frequency conversion type new invention, does not change its output of ozone of operating and can increase 0.5 to 1.5 times under the condition originally . At the same time because efficiency improves by a wide margin , the power consumption is small can reduce a lot of maintenance cost . l Airtight type tube high pressure l The power consumption of ozone of every 1G saves 2 times of electricity for 20-30W: l The electric thick liquid hydrolysises and touches the coal to activate l The power consumption of ozone of every 1G is 10-15W: Province electricity 3-4 times |

High voltage , high power , power consumption are large The power consumption of ozone of every 1G is 40-55W |

|

Power ratio of power consumption of the generator |

150g/h. < 4000-5000w |

150g/ h=8000-8500w |

|

Expose to the sun the angry strength of dissolving |

60-88% |

20-30% |

|

Sterilization strength |

Can kill the unicellular alga , better than UV light, and 600000 times of the chlorine |

Use the structure of the peace and quiet machine of air among the general workshops, whether is it let it produce voltage spark make ozone whether law this disinfect to increase. Can but a thorough one remove air , virus and bacterium of ink rapidly, |

|

Precautions |

Precautions

|

|

3Water

�@

�@

�D ��

���Ͱ��@��O1(��ͺA��)�j���ߤO�����ΨӥR��PH 9���q�u��,�B����ī����p���l���ߤ��C

��PH��(PH=9)�q�u���O�����P���V�X��,�]���@�״��ɷ|���CPH��. �ݦA�[��PH7�t�ƪ�1.7

~2.0��,

���q�q5TON���ɦ�16TON��3��,�@��5���\�v�C

�� ��

�o�O���s��Ϊ����~�űj���ߨt��, �j���߳�� O1,�Į�産�ͬO�����B����۵߲ӭM�o�g�o

������ɼu, �ӳo�ɼu���W�٥��O�ѯ��R�X����� O1, �]���i�H�R爲"������k.. �G�ĥ�3W

�q�ߦ�IJ�ѱj���ߨt�� O1�t�ΡC

�����W�@�����G�V�X�t�η��ѮIJv����, �����(�D��)���A�X���ɶ��B�@.�|�o�Ͱ���

(���C��@��)�B�ӹq,�G�ݰ���j�����@�ײ��Ͷq;

3W���������D���C

�q�ߦ�IJ�� �t���u�I:

1.

���|�o�Ͱ���:�G�ٹq�����⪺30~50%���D���ӹq�q�C

2. ��Φ�����ͮ�O1��O3�����ߤO�Ʀʭ��C"���j���ߪk. Single Electrode Corona

Discharge)���ͧC�ŵ����l��C

3.

���t�ά��W�a�h�q���V�X�k,��G�V�X�t�η��ѮIJv�ά����⪺200~300%�C

4.

�E�o�����l���l�A�_�䤧�L�w�Y���ī������ߤ�

5.

������(a/b�D��)����B�@,�t�ιةR�W�������⪺3-5��

6. �q�ߨt�Ω�q�覡������IJ��O1�t��,�i�������Ѳӵ߮���,�R���ϯ�p���l��,�|�b

���W�Φ���ƥֽ��O�@��,����A���,�i�������ةR�C

�A�νd��

�U�����~�B�s���B�Ƨ��~���~�����r

�������q�u���~�~�R��]�ˬy�{ ������

|

Step 1 |

�ݬ~���Ų~����ðe�ܿ�e�a�W�C

|

|

Step 2 |

�۰ʤW�~�ܬ~�~�� |

|

Step 3 |

�H 3Water����IJ��(��ͺA��)�L�w�B���R�~�~�l�~���ë� 22�� |

|

Step 4 |

�~�ϥ�Final

Rinse ���^�����H�������~�Q�~�C |

|

Step 5 |

�M�~�ϥΧt����R������̫ᤧ�M�~���ߡC

|

|

Step 6 |

�ĤT�q�M�~���߫ᤧ�Ų~,�۰ʰe�J�L�߫ǵ��ԥR�� |

|

Step 7 |

�۰ʰe�\�øg�����߫�A���ݫʻ\�C

|

|

Step 8 |

�۰ʥR��ʻ\��A�e�X���x

|

�q�ߦ�����-����IJ�ѱ��ߺ�X�W�d����(�Ѧҥ�)

�]�ƦW��: �q�ߦ�-IJ�ѱj���ߨt��(�`�����M��)

Microwave &

Dielectric Barrier Discharge of Micron Bubble O1

Water

�B�z��H:

The whole packing facilities of mineral water.

�A�Ω��q�u���Bo2�q�u���]�ơB���� O3�~�~���B�f�A�G�B�ľ��B�s�����~�C

�ᤩ����+���ƥ\��

CD�q�w��q���`�J �[�WDielectric Barrier Discharge -���W�q�ߤ��`�̷L�w�K..�K������

�O�����U,�N���`�J����,�@�譱���r����. �@�譱�~�b��|�b���W�Φ���ƥֽ��O�@

��,����ߦA�קֳt�W�[*�������ޡB�R����B�ʻ\���ةR�C

���W�q�ߤ���IJ�ѱ��� ��Ů�B�®�q�L�q�߰ϮɡA����l��Q���_�A���ͳ���l�A

�A�P��L����l���X �C

���W�q�ߤ��`�̹s�����ݹq�ƾǯS�ʲ��ͶW�j�Ѭr/�L�w�����b��, IJ�Ѿ����ϷL�ɪi��

�l���j�q�j�۵M��q�M���Ǧ��˸m����X�j�O�����b�ƪŮ𤧥\��C��������E�o����

���l�A�A�_��A�j���l�Ƭ��p���l�A�ӹF�쬡�Ƥ���C

3Water�N�S�I

1. ���W�q�ߤ���IJ�ѱ��߰��IJv/�C�����~���Q�����߰���t���n��B��( OZONE)

���@��O3�����������,�ŦX��ڦw���з�,������H�鲣�ͦM�`�C

2.

����IJ��O3�]�ƾA�Ωʰ�:�i�̫Ȥ�B�z�ݨD�]�p�X�A�����C

3.

psa�Q�ΩP�D���Ů�g�L�X���M�Τ��l�z���l���ѧl���j��������

4.

psa�q���Ƴ]��:�i��̵u�ɶ���������f�w�ˤκ��סC

5. �g�٫���]�O�ΡB���@�����C�G:�ʸm�O�ΧC�A�H������A/B�G�t�Υ���B�@24

�p�ɳs����۰ʤƾާ@�A�ϥήIJv���A�Ŷ��M�H�z�A�W��������C�G�B�ϥΦ~�����C

�@

3w���W�q�߮�Ƴ]�ƯS��

�@

Dielectric Barrier Discharge��y��(SIDE�wSTREAM)O3 -MB-A*B*C*D

�|�ؤ��B�z�t��

,�ϥΤ����N���𤧼o�������Ѥ�������X(PUMPS),�q�@��psa���ӷ��Τj�𤤻s�y

O3,���۱N�Q�Τ��Q�Y(VENTURI INJECTOR)�`�J����,�㦳�j�O��O3���߮ĪG,�i�N

�ƭ��C. O3�~�~���Ʀ�������εL������Q�Ϭ~�~���𦬶��òM��,�]���i��֬~��

��ƦìV���C

�`���y�{:�����ߨt�αĥήdzq�`��(��y��)

�����GDielectric Barrier Discharge����IJ�ѻPO3�ަb�P�@�t�Τ��A���o�����W�ߡA�H�T

�O�t��í�w��

�ƶq�G�@�M�t��:�ؤo���o�j��3.5m*3m*2.0m�A�λݰt�X�{���Ŷ��H�Q�ո�

(1)

�c�y�G:

(SS41����~��)����IJ�ѺޥH�ަ��K�ʾɹq�X�����ɡASUS3���]�Ь��ۭ^��)�A�B��

�@����\��A�O�T�@�~�]SUS 304�]��,��o�q�w(Corona Discharge)�覡���Ͱ���

�ױj��Ʈ���A�~�c�i��P�Ʈ��4"�����A�O���q���}�n

(2)�t�γB�z�e�q�G�ܤ֬�0.5-0.8ppm���@�ץH�W(�i�h�ը��p�ϥ�)

(3)�h�q��ƲV�X�G�@�q:�Ĩ��h�h�����ѥH�C��(<2-5kg/cm2 )��������V�X�G�q:�h

��by-pass�Ǭy���l�J�h�l����(��PVDF����A��ܮ�Ƥέ@���P���V�X�ΡA�Q�έt

����z�Ϯ���M���V�X)�ޮ|(1-3��)�A�i��>4�gm�����ϥΤƾ��ľ�,����������B

�G�k�B�����]�ƹةR

(4)�@��:(a)�b�Ů𤤦ܤ�1.66~2.7% wt air�H�W(b����t)�b�h�q��ƨt�Τ���0.50

ppm~0.88ppm�i�tPSA�t��(85~95%)�®���Ͷq

���ιL�o��,��;��ΰf�y���,�妡�ު`�J�f,�y�֡B�f��֡B���O��,�i����

���B�z�]��ON/OFF�W����.

(5)�ʱ��t�ΡG(����t)

�ĥκʵ����ѯ��@����TDS*1(���ѩT��q��ܾ�)�BORP*1(ORP Controller��

���٭�q����ܾ�)�B�Ψӫ��ʱ��`����������٭�q��/�q�ɫפιB��ɺ�O���*1

(6)���O�G>=1HP/2hp�A�J���f1-2���A�ϥΤ����έ@���P�ϥΪ��`�����A�ܮ�ơC

(7)���ո�

(1)�dzq���ϥ�inject�α��֥�(2)��Ʈ�����h�ݱĥΥX�f�����ޮ|��6-

(3)����GAS�f��֥H�����Ʈ���^�y

(8)����t��

�i��İ���Ů�Υi�t�X���O�����l���k(PSA)�����o�;��H�������@��,����

�«ץH85~95%,��۹��S�I��:-60~

(9) �w���譱�q���譱�G�]�w���Mí�w�ާ@�ݰ����a�κ|�q�_����*1.�B��ɫ��J�A��

���ɥ�i�G��ܹq�����b�A���_�q�C

����譱�GPSA�Y�]���O�ηî�Ӥj���YHTYT�������C

(10)

�X�t����(1)�]�ƫ���/�ϭ��Ϥ�2007����ާ@���פ�U�C

�G�B

3Water�j�����~���Q�����s�y�t��-�~�P

(�j�����~�u�~�B�����i���ͤu�{�B�b�����B���~�����B�z���^���u�~�ҾA�X���t

�αĥΡA�i�t��W��)

���u�{�ҨϥΪ����s�y���t�Υ]�t�Ů�s�y�]�I�B��;��B���y�q���t�L�B

���IJ�ѤΤj����}�a�����˸m�C���t�Ωһݤ��\�v�B�ƶq�B�p�]�ƪ��W���

�ҥ� , �I�@�t�������X�]�Ʋӳ��e�f��Ƶ��ؿv�v�η~�D�f�֫�~�o�H�ĥΡC���s

�y�t�γ]�ƪ��@��W�d�p�U�ҥ� :

• �Ů�s�y�]�I : �b���ѵ������һݭn���Ů�~��n�Q�����b�ΰ��� , �]���b���

���i��f�e���]�m�T�պ�K�L�o���B�@�զ۰ʱƤ��˸m�ΧC�Ű�����աC

{�~�P����}

�t�Ʊ��s�y�t�β��;�

:

•

�ĥ�Dielectric

Barrier Discharge��q���ͯ��覡

•

����X�e�q : 300g/hr�C�̳]�ƪ��W���e�q�ݨD�ӭq�C

•

�q�O�ݨD :220V,60HZ •

�j��ū� :5 -40�J •

���ҳq�� :

�C�p�ɦܤ֭n���L�����Ů�q

•

�C�W�N���� CORONA

��

;

�q���N���N�o�q�� •

�Ҧ��Ͳ��Ҳէ��� 316L

���ÿ�

•

�t�䦡�®;�•

���t��������٭�Ȱ������α���˸m�C •

�i�զ�����X�C

• �������ɯ䧹���j�� • �۰ʨѮ�y�q����H�����u�� • �w���Υ�S�p��ܹq�y���Ѫ��A

• �~�c����ŦX NEMA 3R �W�d • ����_�q�O�@ • �����ި� : ����_�q�B���~ĵ���B�Ů�

���@�װ����� ORP

����

•

���~�O�@ :

�ˬy���B�c�����}�B�j�����~�B�Ѯ����O�����B���u�ũιL�ׯu�šB�L���O�@�C

• �Ҧ��j�������O�I���O�@ • �O�T���� : �����O�T1�~�B�����q����1�~ 3. ���y�q���t�L •

�H 304/316

���ÿ��@�����t��[ •

���m 1/ 4�� PVDF

�V�M��

• �C�@�y�q���t�X�f���t�@�ӹq�ϻ֡B�h�� • �įB�I�y�q�p (ROTOMETER),�e�q�� 10L /MIN,

�B�y�H 316

���ÿ����K�t�s����,����H���J�O

���� •

�Ҧ��s���ե��K�t�s����C

•

���t�L�t�@�����]��ʱƤ��˸m

���IJ�� :

•

�� PE

��

FRP

�Ʀ����� (COMPOSITE

TANK)

�C • FRP

�s�@���a��u��¶���C

•

�W�U�}�f���� 3

�^�H�W�T�k�����Y�C •

�R�A���� :150PSI,

�u�@���O�b 50PSI

• �U�h�����㤻�� ABS �콦������ • �W�h�X���� ABS �h�թʴ����� • PVC �T������

�y 5. �j����}�a�� • �}�a���~�ߧ��謰 316 ���ÿ� • ���t�@ 1KW ���[���� • ���t

CUO �M MGO �V�X�����}�aIJ�C• �⭷���e�q���N�����ЪŶ��� 6 �� / �p�� • 316

���ÿ����}�aIJ�C����L • �����Ƥ��˸m

3Water �ë����~��Ĥ@���B���ժA�ȡB���椽�D���g��z���A�W�]���۰� / �b�۰ʯ��~�~�B

����IJ�ѥR��B�ʻ\���B�����߾����A�Ͳ��L�{���b�L�߫Ǥ��R��]��

�@

�q�ߤ���IJ�Ѯ����t�γW��Υ\���(����16ton/0.5PPM)

�@

|

16��/�p��

�� �� |

Model |

S16T-250/280g-D/C |

SJ16t-300g/B |

SJC16t-300g/A |

|

|

�����һݪŶ� |

L��M��H�]�Ѧҡ^ |

120*100*150cm

*3

|

135*110*155cm

*3 |

>150*110*155

*3 |

|

|

16ton���߲v |

% |

99/99.99% |

110% |

120% |

|

|

�B�z�q |

TON |

16 |

16.2 |

16.3 |

|

|

�����@�� |

ppm |

>0.5 |

>0.5-0.6 |

>0.5-0.8 |

|

|

������/�G�t�� |

Engine |

������A/B�G�t����B�@ |

������A/B�G�t����B�@ |

�������G�t����B�@ |

|

|

�L��/�`�̲V�X |

Micron/NANO

bubble

|

�L��/���L�̲V�X |

���L�̲V�X-�L�Ӫw |

�`�̲V�X-�W�L�Ӫw |

|

|

�� �q |

KG |

300-450 |

400-480 |

420-480 |

|

|

�� �� |

Ss41�~�c��/���ަ��o�;� |

SUS304 |

|||

|

�����ۭ^���� |

Ozone output(O3 g /h) |

260/300 |

320 |

320 |

|

|

���@�� |

Concentration |

60/70�H�W |

75�H�W |

80�H�W |

|

|

��/��������J |

Inject Air/O2 |

2/2.5

air |

3.3

Oxygen |

4.5

Asp Oxygen Concentrator |

|

|

��X���O |

Outject -pressure |

0.6/0.8 kg/cm2 |

0.6 |

0.6-1.2kg/cm2 |

|

|

�����\��

�����y�t |

Flow/lpm |

267L/min |

270L/min |

275L/min |

|

|

�E�o�_��L�w���l�A |

Micron |

1 |

0. 5 |

0.05 |

|

|

�N�o�t�� |

Cooling System |

Fan

��6/8 |

Fan

��8 |

Fan

��8 |

|

|

�q������ |

Supply Powder |

220V-50HZ/��V

|

110V-60HZ

220V-50HZ |

110V-60HZ

220V-50HZ |

|

|

�C150g�ιq�q�\�v�� |

150g/h*W |

4500w/4300w |

4300w |

4000w |

|

|

��G�V�X�� |

Inject |

2�� |

2.5�� |

3�� |

|

|

�V�X���� |

Time |

3 |

4 |

5 |

|

|

�ϥιةR/�~ |

Years |

>5 |

>10 |

15 |

|

|

MICRON�L�̪w���l�A

�w������(�ĤG�M�u�f) |

Price�U |

588/689

(538/620�ĤG�M�u�f��) |

900

810(�ĤG�M�u�f��) |

1100

950(�ĤG�M�u�f��) |

|

|

���@��ƪ����� |

O1+O3+micron-B |

������q |

�N�q�w��q

������k |

����q�l(energetic electron������k |

|

|

�~�P���Űt��

|

���q���q�k/�N�q�ߩΧC�Źq��(cold plasmas; nonthermal plasmas, NTPs) |

||||

�@

�K�����ު������o�;�/���O���o�;� �����

|

�o�;� |

�K�����ު������o�;� |

���O���o�;� |

|

���� |

�۷��g�� |

�ӧ��h |

|

���ߪ��覡 |

1.��Φ�����ͮ�O1��O3�����ߤO�Ʀʭ��C"���j���ߪk. Single Electrode Corona Discharge)���ͧC�ŵ����l�� �C 2. O1\O3\�ϯ�,�T�X�@���j���� |

1. ���Ͱ��� 2. ��@O3���ߪk |

|

�ةR |

�ةR��1�~��10-15% ���y�������W�q�y�q�@����A�ҥH�ةR�� |

�ةR�u-1�~��60%

�y�ݩ�q�k�G�q�l���@�קC�A�|���ͤ���A |

|

�s������ϥ� |

���ߪ��ĪG�i�s������ϥΪ�ͺA��o1 |

�s������ϥη|���Ͱ���o3 |

|

�o�;��ιq�q |

���s���ٹq�B�C�\�v�B���@�ת��į�C �������W���s�o���A�����ܨ�즳�ާ@����U�i�W�[ 0.5 ��1.5 �� ����q�C�P�ɦ]���į�j�T�����A�ӹq�q�p�i���C�\�h���@�����C l �K�����ު����� l �C1G�����ӹq�q��20-30W:�ٹq 2�� l �q�ߤ���IJ�Ѭ��� l �C1G�����ӹq�q��10-15W: �ٹq 3-4�� |

���q���B���\�v�B�ӹq�q�j �C1G�����ӹq�q��40-55W |

|

�o�;��ιq�q�\�v�� |

150g/h.< 4000-5000w |

150g/h=8000-8500w |

|

�n�ѤO |

60-88% |

20-30% |

|

���ߤO |

�i������ӭMĦ���A��UV�O�j�A�B�����600~3000�� |

�@��{���ΪŮ�M�b�������c�A��q���[���������ͤ���s�y���Y�O���k ���ߡG�i�H���t�ӹ������M���Ů𤤡B�������f�r�βӵߡA |

|

�`�N�ƶ� |

1. �ϥ� ���� ��,�ФűN ���� ��X�f������ۤf��,�H�K�ˮ`�I�l���x,���I�l�t�ΰ��D��,���Ŷi�J���b�ϥΤ����Ŷ��C �Ŷ����p,�b�p�оާ@ ���� �����O���q���C

|

|

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

���q/����]�����R��

|

|

�~�~�� |

��R�� |

�Ƶ� |

|

���q(ton/h) |

5 |

16 |

|

|

PH |

6.5-7.5 |

8.5-9 |

�ݴ��ɦ�9.5 |

|

�\�v���(���q/PH��/���߲v) |

|

||

|

���߿@��PPM |

0.5-0.8 |

0.5-0.8 |

|

|

���ߪk |

O1\O3\�ϯ�,�T�X�@���j���� |

O1\O3\�ϯ�\�T�X�@���j���� |

��Φ�����ͮ�O1��O3�����ߤO�Ʀʭ��C |

|

�t��� |

A�t�������������B�@ |

A/B�G�t������������B�@ |

|

|

�L��/�`�̲V�X �L�Ӫw |

�L�̲V�X- |

�L��/���L�̲V�X |

��G�V�X�t�η��ѮIJv�ά����⪺200~300%�C

|

|

������ |

�C�W�q�w

|

�L�i�q��

|

���j���ߪk( Single Electrode Corona Discharge)���ͧC�ŵ����l�� �C |

|

����+ED+RO |

�j���ߨt��(��PH�M��) |

||

|